Comparison of CNC machining cost optimization solutions for different materials

Release time:

2025-03-04

The cost optimization scheme of aluminum alloy and stainless steel in CNC machining is mainly concentrated in the cutting process scenario. Aluminum alloy has low density, low hardness, small cutting force and long life; stainless steel has high hardness, high machining difficulty and high cutting force. In turning and milling machining, aluminum alloy has obvious advantages, which improves production efficiency and reduces costs.

In the field of CNC machining, the choice of materials has a significant impact on the machining cost. Aluminum alloy and stainless steel are two common machining materials, each with its own characteristics. Let's compare and analyze their cost optimization solutions in CNC machining, especially focusing on process scenarios such as precision machining and milling.

Basic influence of material properties on machining costs

Aluminum alloy has low density, light weight, and good electrical and thermal conductivity. During machining, due to its relatively low hardness, small cutting force, and light wear on the tool. For example, when precision machining aluminum alloy parts, the tool life is longer and the replacement frequency is reduced, which directly reduces the tool cost. At the same time, lower cutting force means that higher cutting speeds and feed rates can be used, which improves machining efficiency and reduces machining costs per unit time.

Stainless steel has excellent corrosion resistance and high strength, but its hardness is high and machining is more difficult. When CNC milling stainless steel, greater cutting force is required, which not only increases tool wear, but also may cause more heat to be generated during machining, affecting machining accuracy. In order to ensure machining quality, special tools and cutting parameters are often required, which undoubtedly increases tool cost and machining time cost.

Cost Difference and Optimization in Turning and Milling

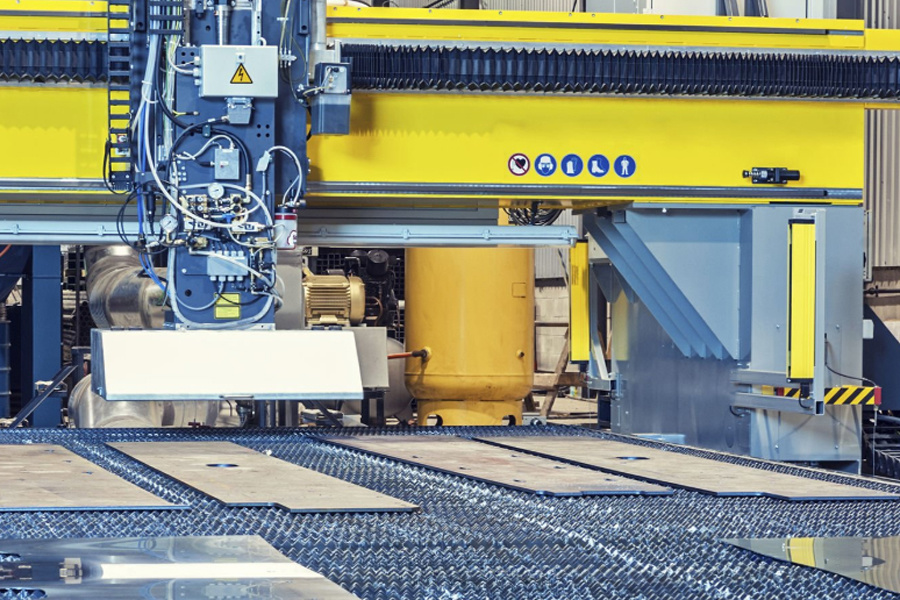

In the turning and milling process, the advantages of aluminum alloy are further highlighted. Due to its good processing performance, aluminum alloy can complete a variety of complex processing procedures in one clamping, reducing the number of clamping times and auxiliary time. For example, when manufacturing aluminum alloy aviation parts, through turning and milling, the processing of outer circles, inner holes, threads and complex curved surfaces can be completed efficiently, greatly improving production efficiency and reducing processing costs.

For stainless steel, although turning and milling can also achieve the processing of complex shapes, due to its high processing difficulty, it requires more sophisticated process planning and higher technical level. In order to reduce costs, it is necessary to select appropriate tool coatings and cutting fluids to improve tool life and processing efficiency. At the same time, optimizing the processing path and reducing unnecessary cutting strokes can also reduce processing costs to a certain extent.

Cost Control Strategy in Precision Machining

In the field of precision machining, both aluminum alloys and stainless steel have extremely high requirements for machining accuracy. For aluminum alloys, due to their good material stability, it is easier to ensure dimensional accuracy and surface quality during precision machining. By reasonably selecting cutting parameters and tools, high-precision machining can be achieved at a lower cost.

In the precision machining of stainless steel, in order to overcome its high hardness and easy deformation, more advanced processing equipment and processes are often required, such as high-precision grinders for precision grinding, which undoubtedly increases equipment investment and processing costs. Therefore, when precision machining stainless steel, optimizing process parameters, adopting advanced tool technology, and strict quality control are the keys to reducing costs.

The cost optimization solutions for aluminum alloys and stainless steel in CNC machining are different. Aluminum alloys have certain advantages in processing cost control due to their good processing performance; although stainless steel is difficult to process, it can also achieve effective cost control through reasonable process optimization and technical selection. In actual production, enterprises should comprehensively select appropriate materials and processing solutions based on factors such as product demand, processing technology, and cost budget to maximize economic benefits.

Related Products

CNC machining multi-axis linkage accurately processes tooth profile and journal size

CNC machining technology plays a core role in the machining of precision gears and shaft parts, achieving high-precision micron-level precision, significantly improving the wear resistance and fatigue resistance of parts, and ensuring the stable operation and high quality of the transmission system. In modern industrial manufacturing, its application in automobile manufacturing, precision instruments, industrial equipment and other fields has significantly improved the overall quality.

2025-06-28

Automotive precision parts processing: Use high-precision gears to drive the future of new energy

The development of new energy vehicles has put forward higher requirements for the precision of parts. The breakthrough of micron-level manufacturing technology has laid the foundation for the stable operation of the power system. High-precision gears are innovatively applied in the energy conversion system of new energy vehicles, which reduces friction loss, improves transmission efficiency and prolongs gear life.

2025-06-18

The manufacturing process of precision accessories in modern medical equipment, especially the use of core processing technologies such as CNC turning and laser micro-welding to achieve precise manufacturing in complex medical scenarios. These technologies not only require precise dimensional control, but also must meet biocompatibility and long-term stability.

2025-06-14

Five-axis machining centers have gradually become the core equipment for the manufacture of complex parts due to their multi-dimensional dynamic machining capabilities. Compared with four-axis equipment, five-axis machining centers significantly improve the machining accuracy and surface quality of special-shaped structural parts through multi-angle synchronous cutting, shortening the production cycle.

2025-06-11