CNC Machining Process

CNC Milling

CNC milling machines process materials into specific shapes through high-speed rotating tools. It can perform face milling, profile milling, drilling, tapping and other operations.

The tools of the milling machine can be replaced as needed to meet different processing needs. At the same time, the material is fixed on the rotatable table, which is convenient for the tool to process from multiple angles.

CNC Turning

CNC turning processing is controlled by a computer and is used to process rotating bodies, such as cylinders, cones, etc. The workpiece is fixed on the chuck and rotates, and the tool moves axially or radially to remove material. Can complete the processing of internal and external circles, end faces, threads and complex contours. All operations are performed automatically based on the CAD model uploaded to the CNC lathe.

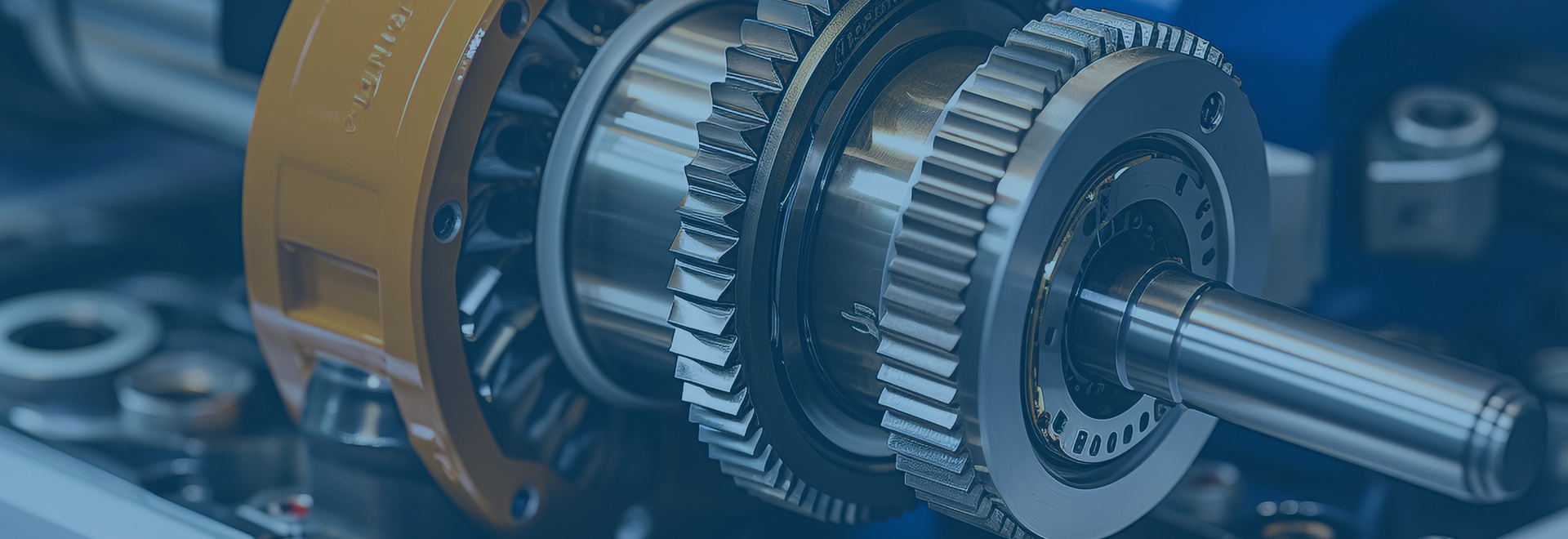

high precision numerical control machining

Power focuses on precision machining design, manufacturing and assembly. High-precision machining includes a variety of gears and various precision parts, which are suitable for various industries.

Power has more than 100+ 3-axis, 4-axis and 5-axis CNC iron cutting machines and CNC lathes are equipped with different types of gear hobbing machines, and provide various processing technologies such as grinding, EDM and laser cutting.

The flexible live production line can meet the full range of requirements from design to rapid prototyping to mass production, and provide you with diversified CNC machining services.

We specialize in manufacturing high-precision high quality machined products according to your budget and delivery requirements.

Fixture Design Capability

With more than 50 independent intellectual property rights, 5 invention patents, fixture design and manufacturing capabilities are widely recognized by the industry.

In the fixture design has rich experience and professional R & D technical team.

Follow national standards to ensure that the fixture processing requirements of different products in different industries are adapted.

Pay attention to the precision and flexibility of the fixture, improve the adjustability and adaptability of the fixture structure, and meet the customized needs of customers for the fixture.

Quality Control

Preliminary inspection of raw materials

Select quality suppliers to ensure that the quality of raw materials is reliable and the material density and material meet the design requirements.

Real-time monitoring of machining process

The implementation of processing standards, the operation of lean management system in the middle of the production of multiple product parameter confirmation, to ensure production stability and accuracy.

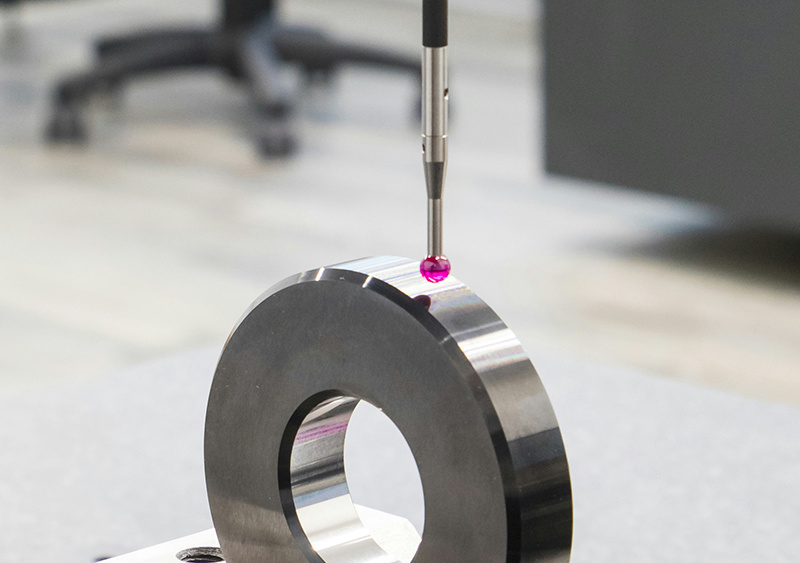

Inspection and evaluation of finished products

According to the finished product quality standards, the use of advanced testing equipment for a comprehensive inspection of the finished product, to ensure that the finished product size, hardness, performance and density and other specifications to meet customer requirements.

Record feedback, continuous improvement

Record the key nodes of quality, timely feedback the test results to the production department, analyze and propose improvement measures, introduce advanced testing technology and equipment, and continuously improve.

Surface Treatment Method

Machining

Tool path marks are left on the surface of the part and no grinding is required.

wire drawing

A line-like texture is formed by scraping the metal surface by the abrasive material.

Nickel plating

A nickel coating is deposited on the metal surface by electroplating or electroless plating to improve corrosion resistance and appearance.

Sand blasting

Use high-speed jet of sand to impact the metal surface to remove dirt, oxide layer and burrs.

electrolytic polishing

The principle of electrolysis is used to form a bright polishing layer on the metal surface to increase the surface finish.

Anti-hand fingerprint

Use special coatings or treatments to reduce the possibility of fingerprints on metal surfaces.

passivation

Chemical methods are used to form a dense oxide film on the metal surface to improve corrosion resistance.

anodic treatment

The electrochemical process of forming a protective oxide film on the surface of a metal.

Processing materials

Steel (stainless steel)

Aluminum

Copper (Brass)

Titanium

Polymer

Why choose us?

Ordering Process

Send demand

Write your needs and leave your contact details

Get Quote

The sales representative will send you a formal quote and other relevant information and generate a quote within 12 hours

processing production

We design the optimal solution for your order and start production immediately

Quality Management

We are solely responsible for ensuring that your order is manufactured in accordance with the standards

Delivery of goods

Continuous layout of global factories and rich international logistics experience to meet the rapid delivery of global