In the new energy era, the "invisible hero" is indispensable

Release time:

2025-02-17

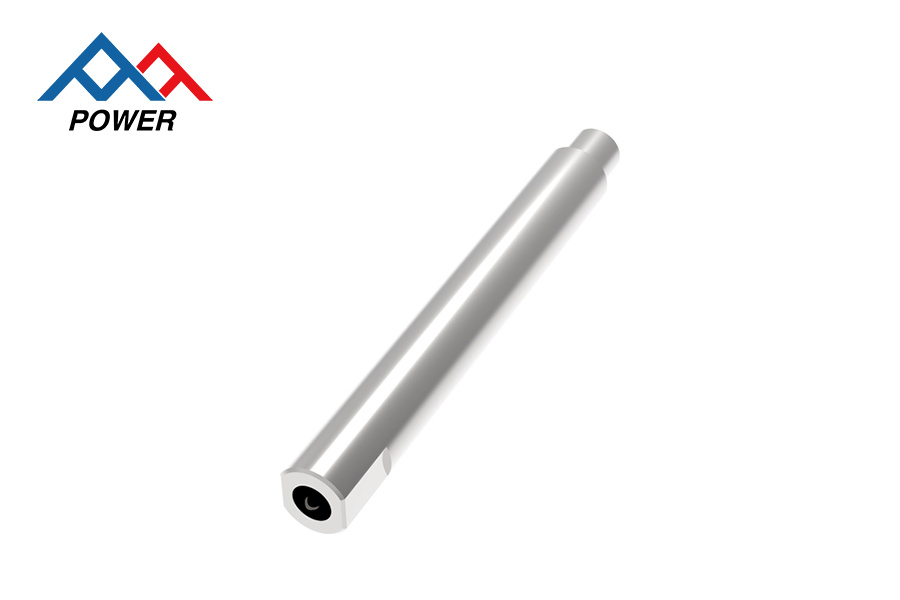

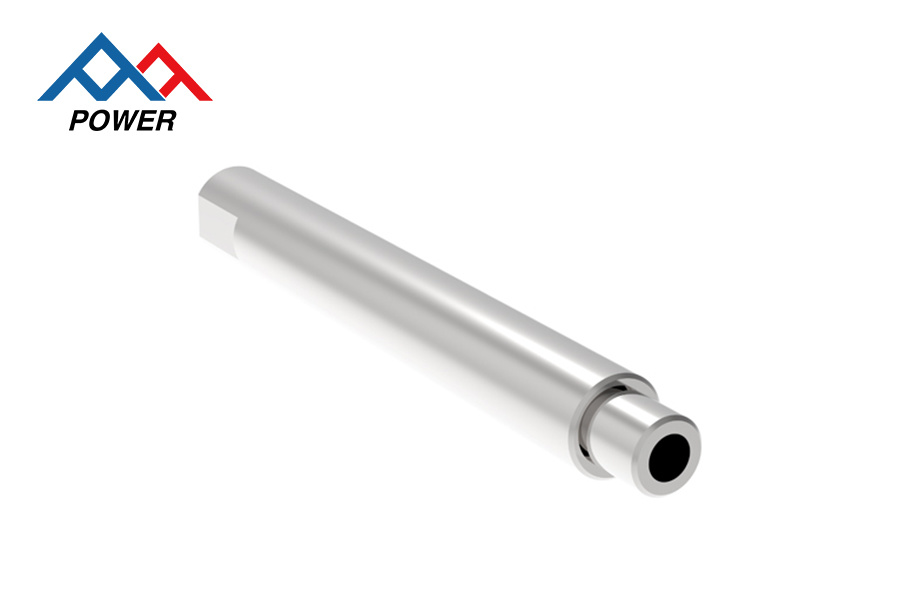

The BFS0002-00064070P1R1 high-precision connection assembly manufactured by Zhuhai Baiwei Machinery Equipment Co., Ltd. provides stable and reliable connection and transmission solutions for new energy equipment through advanced technology and precision design, meeting the stringent requirements of new energy equipment for parts.

In the wave of global energy structure transformation, the new energy industry is rising at an astonishing speed. Whether it is electric vehicles, energy storage systems, or wind and solar power generation, these technologies are inseparable from the support of a series of precision parts. Although these parts are small, they are the core guarantee for the efficient operation of new energy equipment.

Zhuhai Baiwei Machinery Equipment Co., Ltd., as a professional precision parts processing manufacturer, takes advanced technology as the core, relies on high-precision processing equipment and a strict quality management system to ensure that each product meets the micron-level precision requirements. It has profound technical accumulation and rich practical experience in the field of CNC processing and machining manufacturing. From battery connectors to power semiconductors, from cooling systems to smart sensors, every component is contributing to the green energy revolution.

Among them, BFS0002-00064070P1R1 is a high-precision connection component designed specifically for new energy equipment. Its main function is to achieve efficient connection between pipes, cables and other functional components. The core value of this connector is to provide stable and reliable connection and transmission solutions for new energy systems, thereby ensuring efficient energy transmission and continuous and stable operation of the system. Its precision design and high performance characteristics make it play an indispensable role in key applications in the field of new energy.

Baiwei Machinery uses SUS304 stainless steel material in the production of BFS0002-00064070P1R1, which has excellent corrosion resistance, high temperature resistance and mechanical strength, and is very suitable for use in the complex environment of new energy equipment. Through high-precision lathe and milling machine processing, the dimensional accuracy and surface finish of the joint are ensured to meet the stringent requirements of new energy equipment for parts.

With the continuous advancement of new energy technology, the performance requirements for parts will become higher and higher. As a key connector in new energy equipment, the BFS0002-00064070P1R1 produced by Baiwei Machinery will continue to play an important role in technological innovation and process optimization.

In the future, Baiwei Machinery will continue to be driven by innovation and customer-centric, providing smarter and more environmentally friendly precision equipment solutions for the global high-end manufacturing industry, and help industrial upgrading and sustainable development.

Related Products

CNC machining multi-axis linkage accurately processes tooth profile and journal size

CNC machining technology plays a core role in the machining of precision gears and shaft parts, achieving high-precision micron-level precision, significantly improving the wear resistance and fatigue resistance of parts, and ensuring the stable operation and high quality of the transmission system. In modern industrial manufacturing, its application in automobile manufacturing, precision instruments, industrial equipment and other fields has significantly improved the overall quality.

2025-06-28

Automotive precision parts processing: Use high-precision gears to drive the future of new energy

The development of new energy vehicles has put forward higher requirements for the precision of parts. The breakthrough of micron-level manufacturing technology has laid the foundation for the stable operation of the power system. High-precision gears are innovatively applied in the energy conversion system of new energy vehicles, which reduces friction loss, improves transmission efficiency and prolongs gear life.

2025-06-18

The manufacturing process of precision accessories in modern medical equipment, especially the use of core processing technologies such as CNC turning and laser micro-welding to achieve precise manufacturing in complex medical scenarios. These technologies not only require precise dimensional control, but also must meet biocompatibility and long-term stability.

2025-06-14

Five-axis machining centers have gradually become the core equipment for the manufacture of complex parts due to their multi-dimensional dynamic machining capabilities. Compared with four-axis equipment, five-axis machining centers significantly improve the machining accuracy and surface quality of special-shaped structural parts through multi-angle synchronous cutting, shortening the production cycle.

2025-06-11